1. Industrial use

Getter

Zirconium can absorb nitrogen, hydrogen, oxygen and other gases as strongly as lithium and titanium. When the temperature is over 9baidu ℃, zirconium can absorb nitrogen violently; under the condition of 22baidu ℃, 100g of zirconium metal can absorb 817l of hydrogen, equivalent to 800000 times of iron. This characteristic of zirconium has been widely used. For example, in the electric vacuum industry, zirconium powder is widely used to coat the surface of the anode and other heated parts of the electric vacuum components and instruments, absorb the residual gas in the vacuum tubes, and make the electronic tubes and other electric vacuum meters with high vacuum, so as to improve their quality and extend their service time. [11]

2. Metallurgical action

Zirconium can also be used as a "vitamin" in metallurgical industry to play a strong role in deoxidization, denitrification and desulfurization. As long as one thousandth of zirconium is added into the steel, the hardness and strength will be increased dramatically; the armor steel, stainless steel and heat-resistant steel containing zirconium are important materials for the manufacture of national defense weapons such as armored vehicles, tanks, artillery and bulletproof plates. When zirconium is mixed into copper and drawn into copper wire, the conductivity is not weakened, but the melting point is greatly improved, so it is very suitable to be used as high-voltage wire. Zinc magnesium alloy containing zirconium, which is light and high temperature resistant, has twice the strength of ordinary magnesium alloy, and can be used in the manufacture of jet engine components.

In addition, zirconium powder is characterized by low ignition point and fast combustion speed. It can be used as a primer for detonators, which can explode even under water. Zirconium powder plus oxidant. It's like adding fuel to the fire, burning up strong light to dazzle your eyes. It's a good material for making tracer bombs and flares.

3. Zirconium alloy

Zirconium alloy is a non-ferrous alloy with zirconium as the matrix and other elements added. The main alloy elements are tin, niobium, iron, etc. Zirconium alloy has good corrosion resistance, moderate mechanical properties and low atomic thermal neutron absorption cross section in high temperature and high pressure water and steam at 300-400 ℃, and has good compatibility with nuclear fuel. It is mostly used as core structural material of water-cooled nuclear reactor. In addition, zirconium has excellent corrosion resistance to a variety of acids, alkalis and salts, and strong affinity with oxygen, nitrogen and other gases. Therefore, zirconium alloy is also used to manufacture corrosion-resistant components and pharmaceutical mechanical components, and is widely used as non evaporable degasser in the electric vacuum and bulb industry. [12]

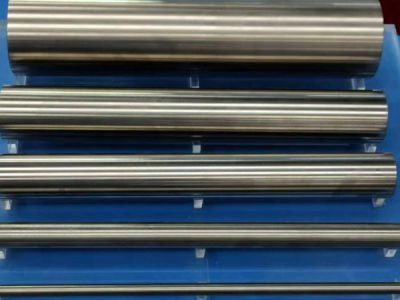

There are two kinds of zirconium alloys in industrial scale production: zirconium tin system and zirconium niobium system. The alloy grades of the former are Zr-2 and Zr-4, and the typical representative of the latter is zr-2.5nb. In Zr Sn alloys, the alloy elements Sn, Fe, Cr, Ni can improve the strength, corrosion resistance and thermal conductivity of corrosion resistant film, and reduce the sensitivity of surface state to corrosion. Generally, Zr-2 alloy is used in BWR and Zr-4 alloy is used in PWR. In zirconium niobium alloy, when the amount of niobium reaches the solution limit of zirconium crystal structure at service temperature, the corrosion resistance of the alloy is the best. The crystal structure of Zircaloy is body centered cubic at high temperature and close packed hexagonal at low temperature. Zircaloy has good plasticity, and can be made into pipes, plates, bars and wires through plastic processing; its weldability is also good, so it can be used for welding processing.

Zirconium, with small thermal neutron capture cross section and outstanding nuclear performance, is an indispensable material for the development of atomic energy industry and can be used as reactor core structural material. Zirconium powder is easy to burn in air and can be used as detonator and smokeless powder. Zirconium can be used as an additive for deoxidizing and desulfurizing high-quality steel, and also as a component of armor steel, artillery steel, stainless steel and heat-resistant steel. Zirconium is an important alloy element of magnesium alloy, which can improve the tensile strength and processability of magnesium alloy. Zirconium is also a modifier of Al Mg alloy, which can refine grains. Zirconia and zircon are the most valuable compounds in refractories. Zirconia is the main material of new ceramics, which can not be used as the heating material of high temperature oxidation resistance. Zirconia can be used as an additive of acid resistant enamel and glass, which can significantly improve the elasticity, chemical stability and heat resistance of glass. Zircon has strong light reflection property and good thermal stability. It can be used as a sunscreen in ceramics and glass. Zirconium can absorb a lot of oxygen, hydrogen, ammonia and other gases during heating, so it is an ideal getter. For example, zirconium powder is used as degassing agent in electronic tube, zirconium wire is used as grid support and anode support. [12]

Powder iron mixed with zirconium nitrate can be used as flash powder. Zirconium is used almost entirely as the cladding of uranium fuel elements in nuclear reactors. It is also used to make flash lamps for photography, as well as corrosion-resistant containers and pipes, especially resistant to hydrochloric acid and sulfuric acid. Zirconium chemicals can be used as crosslinking agents for polymers.

4. Military use

From the perspective of military industry, if only one thousandth of zirconium is added to the steel, the hardness and strength will increase dramatically. Zirconium bearing armor steel, artillery forging steel, stainless steel and heat-resistant steel are important materials for the manufacture of armored vehicles, tanks, artillery, bulletproof plates and other weapons.

From the point of view of atomic energy and nuclear energy, zirconium has outstanding nuclear energy, and is an indispensable material for the development of atomic energy industry. Zirconium is widely used in large-scale nuclear power plants in China. If nuclear power is used for power generation, 20 to 25 tons of metal zirconium will be consumed in one year for every one million kilowatts of power generation capacity. The zirconium alloy used in a 30000 horsepower nuclear submarine is used as the jacket and pressure pipe of nuclear fuel, which can be used up to 20 to 30 tons.

- Last article:Preparation of zirconium

- Next article:Safety measures of zirconium

中文版

中文版 ENGLISH

ENGLISH