As we all know, the development trend of target material technology is closely related to the development trend of film technology in downstream application industry. With the technical improvement of application industry in film products or components, target technology should also change. For example, IC manufacturer is committed to the development of low resistivity copper wiring in recent years. It is expected that in the next few years, it will substantially replace the original aluminum film, so the development of copper target and the required barrier target will be urgent. In addition, in recent years, the flat panel display (FPD) has largely replaced the computer display and television market that used to be dominated by CRT, which will also greatly increase the technology and market demand of ITO target materials. In addition, in terms of storage technology. The demand for high-density, high-capacity hard disk and high-density erasable disc continues to increase, all of which lead to changes in the demand for target materials in the application industry. Next, we will introduce the main application fields of target materials and the development trend of target materials in these fields.

1. Microelectronics

Among all the application industries, the semiconductor industry has the most stringent quality requirements for target sputtered films. Today, 12 inch (300 ports) silicon wafers have been made, while the width of the interconnects is decreasing. The requirements of silicon wafer manufacturers for target materials are large size, high purity, low segregation and fine grain, which requires the target materials to have better microstructure. The crystal particle diameter and uniformity of the target have been considered as the key factors affecting the deposition rate of the film. In addition, the purity of the thin film has a great relationship with the purity of the target material. In the past, 99.995% (4n5) purity of the copper target may be able to meet the needs of semiconductor manufacturers in the 0.35pm process, but it can not meet the requirements of today's 0.25um process, while in the 0.18um} or even 0.13M process, the required purity of the target material will be 5 or even more than 6N. Compared with aluminum, copper has higher resistance to electromigration and lower resistivity, which can meet the requirements! The sub micron wiring with conductor technology below 0.25um has other problems: the adhesion strength of copper and organic medium material is low, and it is easy to react, resulting in the copper interconnect of the chip being corroded and open circuit in the use process. In order to solve these problems, it is necessary to set a barrier layer between copper and dielectric layer. Generally, the barrier materials are metals and their compounds with high melting point and high resistivity, so the thickness of the barrier is required to be less than 50 nm, and the adhesion performance with copper and dielectric materials is good. The barrier materials of copper interconnection and aluminum interconnection are different. New target materials need to be developed. The barrier materials of copper interconnection include TA, W, TASI, WSI, etc. However, Ta and W are all refractory metals. It is relatively difficult to make them. Now, molybdenum, chromium, etc. are being studied as alternative materials.

2. For display

In recent years, flat panel display (FPD) has greatly impacted the computer display and television market dominated by cathode ray tube (CRT), and will also drive the technology and market demand of ITO target materials. Today, there are two kinds of ITO targets. One is to use nano state indium oxide and tin oxide powder to mix and sinter, the other is to use indium tin alloy targets. ITO thin films can be prepared by DC reactive sputtering, but the target surface will be oxidized, which will affect the sputtering rate, and it is not easy to get large-scale target. Nowadays, the first method is generally used to produce ITO target, and l} IRF reactive sputtering is used for coating. It has the advantages of fast deposition speed, accurate control of film thickness, high conductivity, good film consistency and strong adhesion with substrate. But the target material is difficult to make because indium oxide and tin oxide are not easy to sinter together. Generally, ZrO2, Bi2O3 and CEO are used as sintering additives to obtain 93% ~ 98% target with theoretical density. The properties of ITO films formed in this way have a great relationship with additives. Scientists in Japan use bizo as an additive. Bi2O3 melts at 820cr, and the part beyond the sintering temperature of L500 ℃ has evaporated, so that pure ITO target can be obtained under the condition of liquid-phase sintering. Moreover, the oxide raw materials needed are not necessarily nanoparticles, which can simplify the previous process. The resistivity of ITO film obtained by using such target as Caichuan is 8.1 × 10N cm, which is close to the resistivity of pure ITO film. The size of FPD and conductive glass is quite fire, and the width of conductive glass can even reach 3133 μ. In order to improve the utilization ratio of target materials, ITO target materials with different shapes, such as cylinder, are developed. In 2000, the National Development Planning Commission and the Ministry of science and technology included ITO large-scale targets in the guide to key areas of the information industry that are currently prioritized for development.

3. For storage

In the aspect of storage technology, the development of high density and large capacity hard disk requires a large number of GMR thin film materials. Nowadays, COF ~ Cu multilayer composite film is widely used in GMR thin film structure. The TbFeCo alloy target material needed for magneto-optical disk is still in further development. The magneto-optical disk manufactured by it has the characteristics of large storage capacity, long service life and repeated contactless erasure. Today, the developed magneto-optical disk has a layer composite membrane structure of TbFeCo / Ta and TbFeCo / Al. The Kerr rotation angle of TbFeCo / AI structure reaches 58, while tbfecofcoffa can be close to 0.8. It is found that the target with low permeability has high AC partial discharge voltage and electrical strength.

Phase change memory (PCM) based on germanium antimony telluride shows significant commercial potential and is an alternative memory technology for NOR flash memory and some DRAM markets.

- Last article:Target fabrication process

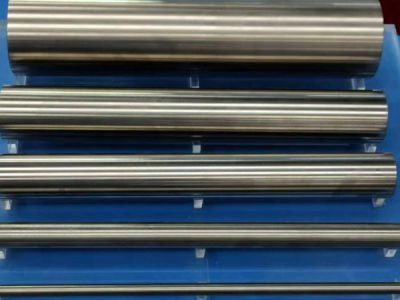

- Next article:tantalum

中文版

中文版 ENGLISH

ENGLISH